Equipment & Materials

Quality is always

at the forefront.

By using high quality equipment and products, we can ensure the best result’s.

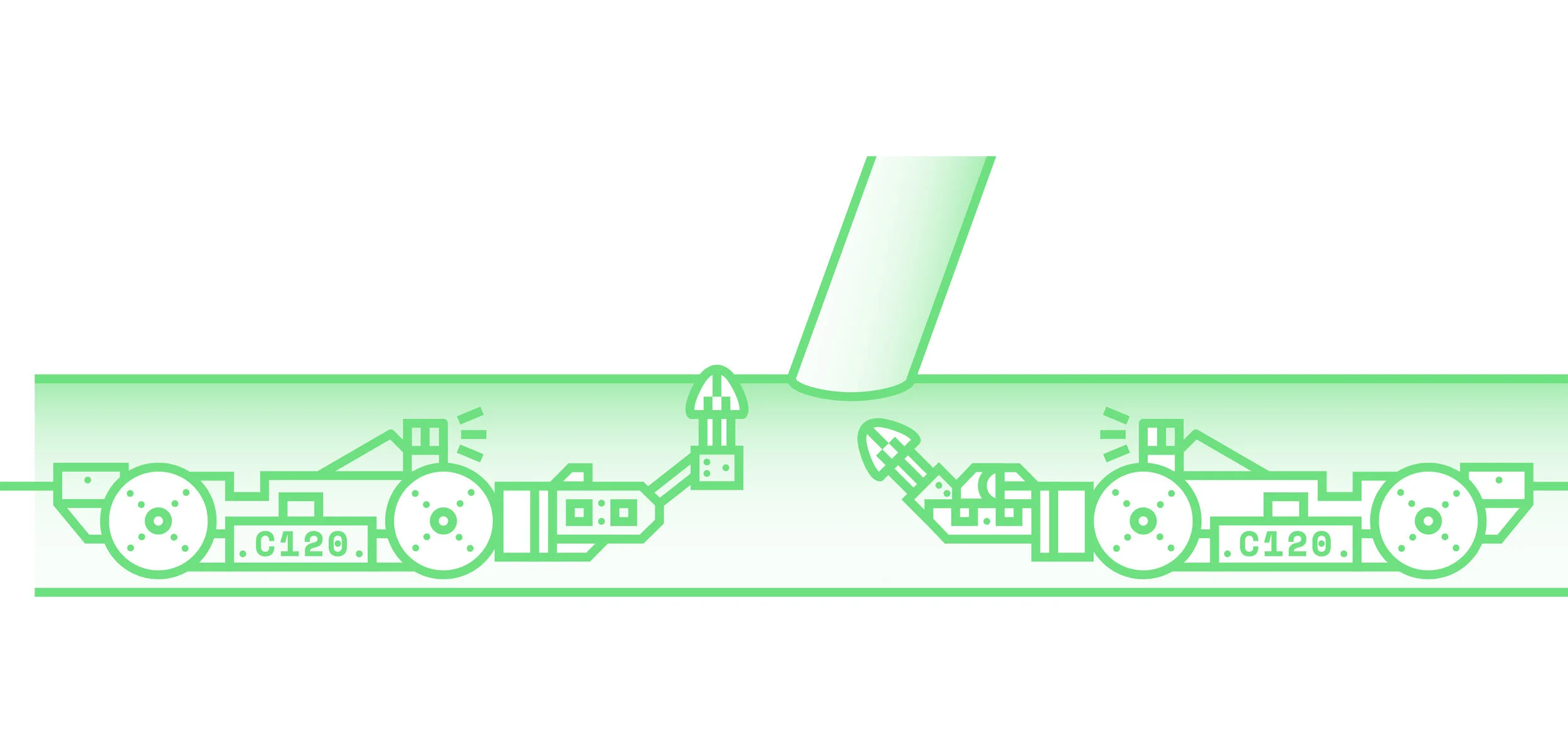

Mainline Robotics

Cosmic™ Robotics

PipeMedic’s C120 Cosmic™ Robot is a world leading, all in one investigation segment repair system. The C120 is fully adaptable to pipelines from 150-600mm in diameter.

The Cosmic™ rehabilitation system is capable install UV cured TopHat and Patch repairs in 15 minutes preventing the need for a bypass. The rehabilitation material consists of a GPR Materials which is unable to shrink and is self-supporting. The adhesive is certified for 50 years.

Cosmic™ Capabilities:

| TV in the main pipe | CCTV Camera + Robot |

|---|

| Cutting the main pipe | Cutter + Robot |

|---|

| TopHat in the main pipe | TopHat + Robot |

|---|

| Patching the main pipe | Short Liner / Patch + Robot |

|---|

| Lateral Pipe TV Launching | LJR CCTV Camerta + Robot |

|---|

| Lateral Cleaning & Root Cutting | LJR Cleaner, Cutter + Robot |

|---|

CIPP Lining Products

Brawoliner® CIPP

PipeMedic have been exclusively using Brawoliner® CIPP products for pipelining since the establishment of the company. Its performance and quality allows our certified installers to maintain a perfect track record for both commercial and residential applications.

PipeMedic values quality above all else. For this reason, Brawoliner® CIPP products have been chosen to ensure a long-lasting, high quality finish. Brawoliner sophisticated-quality has received the best result in all assessment criterias for IKT (Institute for Underground Infrastructure) testing is based on effectiveness, density and load-carrying capacity.

| BRAWOLINER® is DIBt-approved for the renovation of underground pipes (Z-42.3-362) and of pipes laid inside buildings (DIBt Z-42.3-499) and conform to various international standards (QUiK, kiwa & WRC CP308), while fulfilling the requirements of BS EN ISO 11296-4:2011, passing the Thames Water Infiltration Test & the IKT product test in standard and in extreme situations. During the extensive functional check BRAWOLINER® XT received the best results in all assessment criterias (effectiveness, density & load-carrying capacity of the structure). |

|---|

Liners

For mainline liners, PipeMedic chooses a Brawoliner® seamless textile hose with a seamless foil coating. The Brawoliner system is available in diameters of 50-400mm and has the following advantages:

| Able to cope with multiple bends of up to 90° |

|---|

| Can handle with one change in pipe dimension |

| Simple and problem free installation |

| Gentle inversion pressure from as little as 0.2 bar possible |

| Can be used to fix most damage |

| Top performer in the IKT product test |

| Successfully passed the UK Water Infiltration Test |

CIPP Resins

For for residential and commercial applications, PipeMedic has chosen Brawo® epoxy resins for the renovation of domestic and industrial pipeline systems. The Brawo® resins have the following advantages:

| Ambient and warm curing |

|---|

| Excellent mechanical properties |

| Environmentally friendly when fully hardened |

| High abrasion resistance |

| Durability over 50 years |

| Solvent-free |

| High chemical resistance |

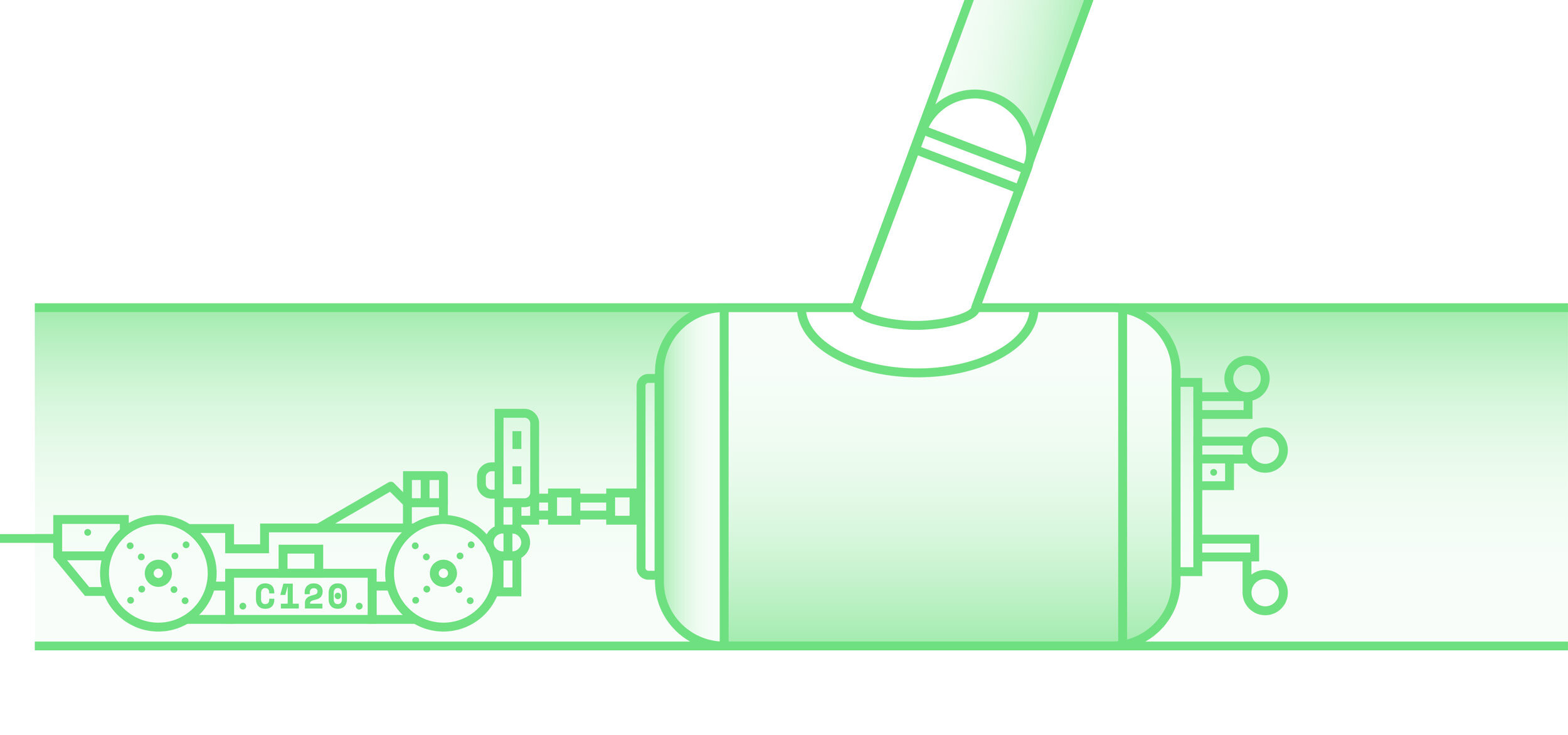

Patching Systems

Epros® Patch

Repair System

Ø 50—1200mm

To repair small segments of damaged pipelines, PipeMedic uses the Epros® Drain Packer System for pipeline sizes DN50-DN1200. This system uses silicate resins and chemically resistant CRF+ glass fibre. Coupled with high quality materials and experienced technicians, these patch repairs have a service life of 50+ years.

| 600DN Patch Repair |

|---|

Advantages:

| High Chemical and Heat Resistance |

|---|

| Short curing time frame (1 to 3 hrs) |

| Suitable for all types of pipeline materials |

| Virtually no shrinkage (< 0.6 %) |

| Tested to IKT, ASTM, WIS and DIN EN pipeline standards |

| Service life of 50+ years |

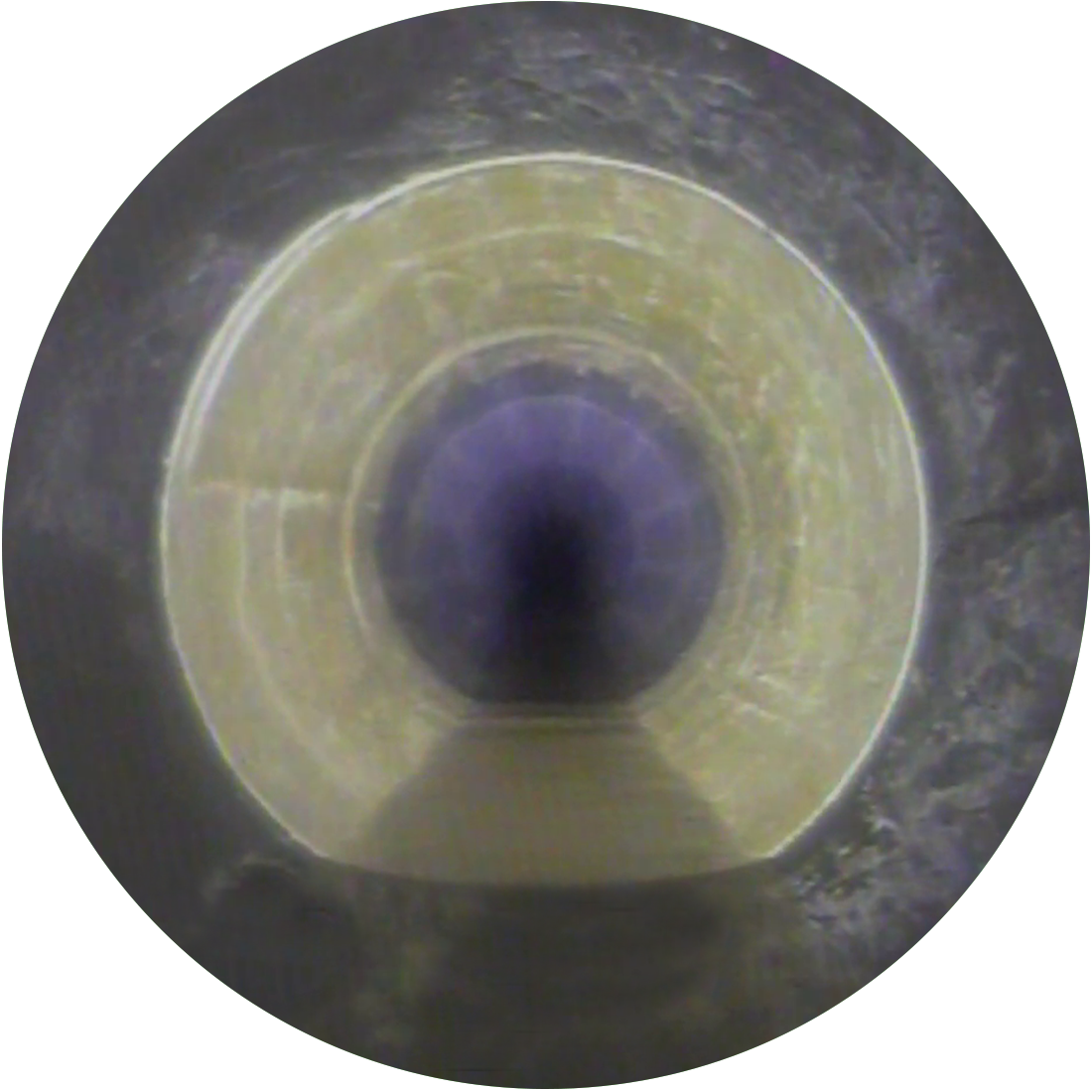

CCTV Cameras & Diagnostics

CCTV Push Cameras

Ø 50—500mm

Designed to capture video footage of long / short lengths of small diameter pipelines, typically ranging from 50-150mm (capabilities up to 500mm). These are mobile units that are capable of navigating through multiple bends and debris to inspect the condition of the drains.

PipeMedic utilises three different types of push cameras depending on the condition, configuration and access to the pipeline.

| SoloPro Plus |

|---|

| Rigid SeeSnake® |

|---|

| Brawoliner® GEJOS |

|---|

Mainline CCTV

A mainline camera is required to complete detailed pipeline assessments in larger pipelines. PipeMedic chooses a Ipek Rovion CCTV System to complete inspections in pipelines from DN100 - DN2000.

The iPek Rovion Crawler is suitable for inspecting pipelines from DN 100 up to DN2000. This system has a range of modular accessories that allows the crawler to be configured for many different inspection tasks. The Rovion crawler has a robust and smart design to perform well in adverse conditions. The intuitive operability and elaborated construction allows PipeMedic to perform high quality pipeline inspections to meet KPIs and satisfy the customers needs.

| iPEK Rovion® CCTV Inspection System |

|---|

The iPek Rovion CCTV Inspection System has the following market advantages:

| Powerful & Steerable 4WD | Minor debris or objects do not stop the camera in its tracks |

|---|---|

| Electronically Operated 2-Speed Gearbox | Drive faster and further to achieve more from the same manhole setup |

| Fully Automatic Light Weight 300m Cable | Additional speed and length |

| Automatic Camera Centering | Confirm correct clock position and centre position |

| Location Transmission | Locate defects and points of interest from above ground upto 6m of depth |

|---|---|

| 3-Point Laser Profiling System | Accurately measure the diameter or the pipeline and detect deformations and defects |

| Flow Monitor System | Calculate flow and identify dips |

| Touch Screen Portable Control Panel | Operation can be supervised and controlled from rear of vehicle |

Lining Cutters

IMS Micro Light Lateral Cutter

Ø 80—150mm

The IMS Micro Light lateral cutter is used in pipelines with diameters ranging from 80mm to 150mm. The powerful air-powered motor and flexible design makes easy work of cutting in complex pipeline configurations.

Capabilities:

| Liner Trimming | Root Removal |

|---|---|

| Grout Removal | Rebar Removal |

| Lined Junction Openings | Pipeline Reshaping |