Key Capabilities

Our Services

No-Dig Pipeline

Repair Specialists

PipeMedic is a specialist in completing

No-Dig pipeline repairs. Our goal is to save our clients money, time and disruption by preventing the damage/excavation of above ground assets and surfaces.

Before you dig or remove surfaces, PipeMedic can diagnose your pipeline and offer a repair strategy that can be fully trenchless or partly trenchless for the most time and cost effective solution.

No-Dig Pipeline Repairs

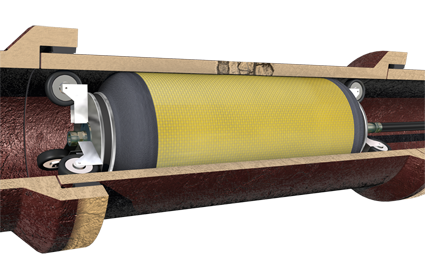

PipeMedic is a certified installer of Brawoliner® CIPP products. We have chosen this system for its superior quality and performance in the 50-400mm diameter range.

Brawoliner® products are extremely flexible due the special loop construction. This makes it the ideal renovation solution for defective pipes with bends of up to 90° and up to two changes in dimension. Brawoliner® has a working life over 50 years, offering an economic and environmentally friendly alternative to traditional trench and relay techniques. We have chosen this system for its superior quality and performance in the 50-400mm diameter range.

Full Pipeline Rehabilitation

Cured-In-Place Pipe (CIPP) Lining

CIPP is a trenchless rehabilitation method used to repair existing pipelines. This is a jointless, seamless, pipe-within-a-pipe that increases the hydraulic performance. PipeMedic technicians assess the faulty pipeline and design the CIPP liner to be installed in accordance to the relevant loading conditions and specifications.

Short Liner

Patch Repair

Ø 50—1200

Patching is a short version of Cured-In-Place Pipelining.

If the damage is isolated, a short repair can be installed to save a significant amount of time and money.

PipeMedic has a wide range of patching equipment and materials for damaged pipelines DN50-DN1200 and lengths up to 3m long.

| Before |

|---|

| After |

|---|

Full Manhole Rehabilitation

Manhole Injections

PipeMedic uses a range of MC-Fastpack injection resins to quickly stop water infiltration and leaks prior to the rehabilitation of the manhole.

Once an infiltration point is found a hole is drilled and an injection nozzle is inserted. The resin is injected into the nozzle using a pneumatic tool and two-chamber resin cartridges. The resin once mixed foams into the void sealing up the infiltration.

Manhole Waterproofıng

PipeMedic uses Ombran-W ready-mix mortar to permanently stop leaks and water instructions in manholes.

The product is mixed with water to create a rapid-curing, expanding plugging mortar. This can then be pressed into the leaking points to permanently stop infiltration.

Manhole Structural

& Chemical Repairs

Pipe Medic uses Ombran MHP-SP products for coating, re-profiling and providing high chemical resistance to manholes.

The manhole is first scoured, cleaned and primed. The product is mixed into a mortar which is plastered onto the manhole surface. Once dry the manhole is now fully rehabilitated.

Junction Repairs

Junction Repairs

Ø 70—100mm

PipeMedic uses BRAWOLINER® Connection collars to repair faulty junctions for D100 to DN150 main pipes and DN70 to DN150 branchlines. This system is flexible and tight-fitting to allow for a fast, easy, affordable and reliable solution.

| Stages of Lateral Junction Repair → |

|---|

Junction Repairs

Ø 150—600mm

PipeMedic uses Cosmic™ TopHat system to seal faulty junctions for DN150 to DN600 main pipes and DN100 to DN200 branch lines.

This system is capable of installing UV cured junction repairs in 15 minutes preventing the need for bypass and expensive TMP plans. The rehabilitation material consists of a GRP material which is unable to shrink and is self-supporting. The adhesive is certified for 50 years.

| Before |

|---|

| After |

|---|

Pipeline Maintenance

| Before |

|---|

| After |

|---|

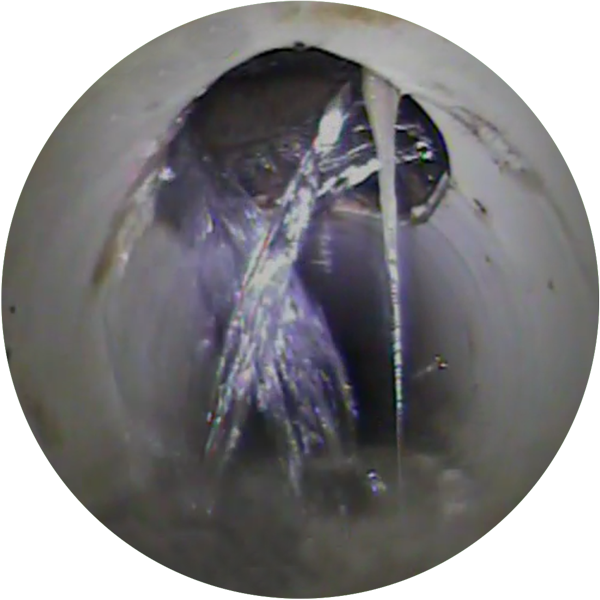

Root Removal

& Prevention

Roots can cause serious problems in pipelines when they continually grow and expand to seek nourishment. They can decrease the flow of the pipelines, cause blockages and further deteriorate the asset. Once you detect roots in your system it is important remove them and seal the pipeline before the damage becomes unrepairable. To prevent further root intrusions and maintenance costs, a patch repair can be installed to seal the pipeline.

PipeMedic has a wide range of root removal equipment for both light and heavy cases. Precision robots can also be used to carefully remove roots if the integrity of the pipe is volatile.

Obstruction

Removal

PipeMedic has a variety of robotic cutters and tools to remove any defects or obstructions in a pipeline without the need to dig up the pipe.

The most common types of obstructions are:

| Grout / Concrete | Rebar |

|---|---|

| Protruding Laterals | Slipped Rubber Rings |

| Broken Pipe Segments | CIPP Defect Removal |

| Cutting Protruding Lateral in 400mm Pipeline |

|---|

Pipe Stop

Ø 70—250mm

Unused pipelines can cause significant problems for the system as they are typically not maintained, allowing roots and rodents into the system.

Pipe Stop is used for closing unused/dead pipelines ranging from DN70 to DN250. The device consists of woven fabric impregnated with an epoxy resin. The device is then pushed into place, inflated and disconnected. A non return valve keeps the device inflated long after the resin has cured and the pipeline is now closed and sealed.

Pipeline CCTV & Diagnostics

Pipeline CCTV Assessments

Ø 50—2000mm

To save money and time on drain repairs, it is important that an accurate assessments are completed by competent technicians using high quality equipment.

Our CCTV technicians complete regular third party training and are experienced in accordance to the NZ Pipe Inspection Manual.

Pipeline CCTV also plays an important role in the rehabilitation of defective pipes. Before renovation work begins, video footage is recorded to show the current condition of the pipe. With this information our diagnostics team can produce a comprehensive assessment report detailing the condition of the pipeline and the recommended repair methods. Final inspections are also conducted to prove a successful rehabilitation.

| Although PipeMedic primarily specialises in No-Dig repairs, a trenchless solution is not always the most effective solution. PipeMedic will always provide a non-bias assessment and will continue to work with top quality Drainage, Plumbing and Construction companies to provide the best fit for every situation. |

|---|